News

What should we pay attention to when processing stainless steel roll

- 29 Jul,2016

When machining stainless steel rolls, the addition of cooling lubricants can actually greatly reduce the cutting heat and cutting force during the cutting process. In this regard, we actually need to pay much attention to its ignorance, in order to extend the service life of tools, on the other hand can also guarantee the smoothness of stainless steel coil products.

Shejin is an honest and professional steel supplier in China;

Stainless steel plate in processing, you can choose to use emulsion. But for products requiring high finish, the use of stainless steel special cutting oil should pay attention to. Drilling can be done in the job using a full grind drill and adding a satisfactory coolant. 316 or 303 tapping, that is, we should pay attention to the use of surface thread tapping, the more common is the national standard 304, there will be 301,202 and so on.

So in fact, we should pay attention to the stainless steel roll with tapping oil most tapping oil is a jin, is a gray plastic bottle, the normal price of 33-35 a bottle. With this oil, the silk will be smoother, and none of them will appear rotten teeth.

However, when processing stainless steel rolls, we must actually pay attention to the fact that the oil is thick, in order to pay attention to the addition of resistance, the liquid cannot be used to extract copper and aluminum.

The above is about stainless steel roll processing when to pay attention to what, if there is no understanding of the place, you can contact us or leave a message.

- Best Sellers

-

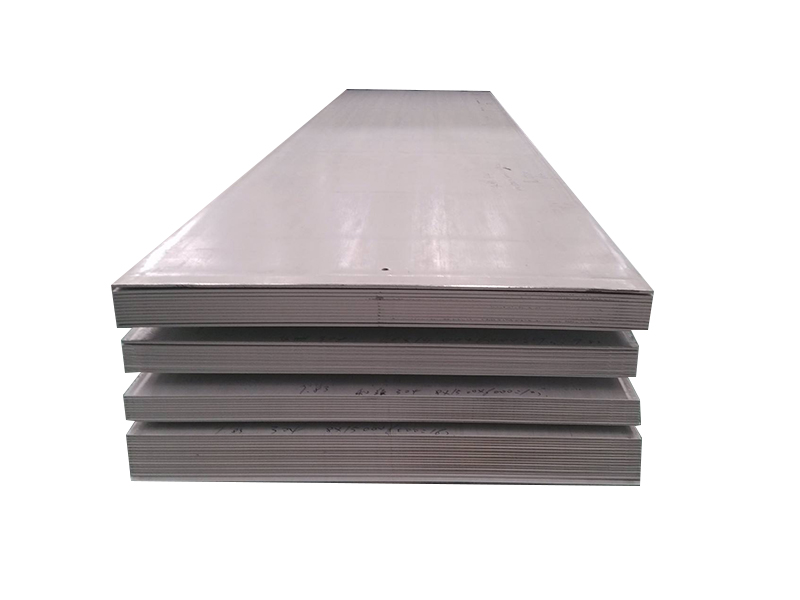

High Quality ASTM Stainless Steel Plate 8K 304L 304 321 316L 310S 430

-

Hot Dipped Zinc Coating Iron Steel Sheets Z60 Z120 Z180 Regular Spangle Galvanized Steel Coil

-

G350 G550 Spcc Galvanized Steel Sheet Coil Prepainted Dx51d For Roofing Sheet

-

ASTM AISI 201 202 304 304L 316 316L 410 410s 430 2b No. 4 Mirror Polished Finished Cold Rolled Stainless Steel Coil for Building Material